Certified and Approved by :

![]()

![]()

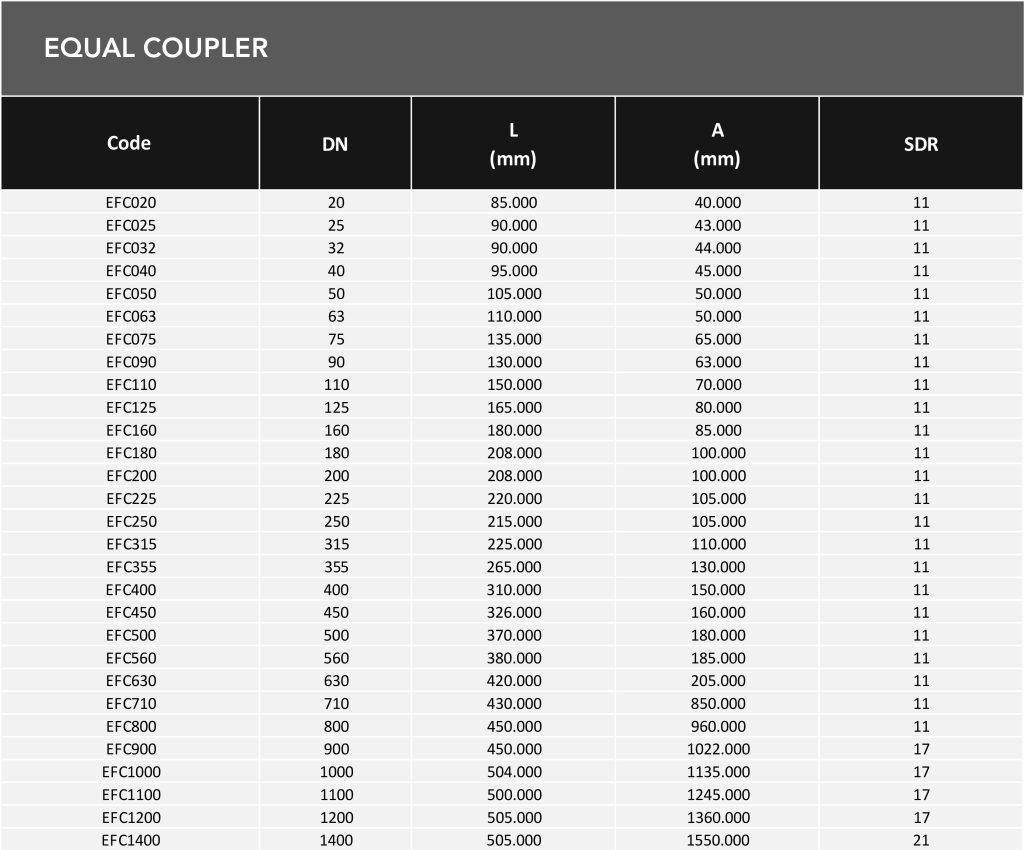

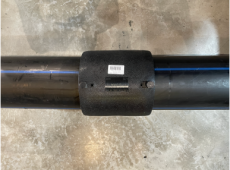

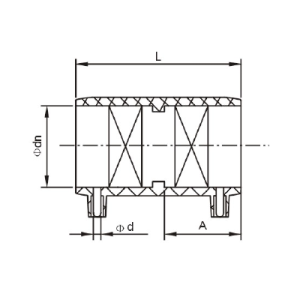

FUIS Electrofusion - Equal Socket

PE100 - PN10 / 16

Product Group : Fuis Electrofusion Fitting

Application : Potable water distribution, Irrigation, Gas, Mining

Electrofusion coupler are used to joint two separate HDPE Pipe in a parallel manner. The jointing using Electrofusion are homogenous, i.e. the fitting and pipe are welded together thus preventing any leakage.

Standard and Certification

- O-rings: EPDM

- Body: Welded steel S235JR (St.37-2)

- Valve sealing: EPDM

- Disk: Welded steel S235JR (St.37-2)

- Butterfly valve stem: Stainless steel 1.4021

- Shaft bearing: Zincfree bronze

- Seat: Stainless steel, microfinished

Questions about the product?

Our experts will gladly answer your questions and support you competently and reliably!

Resilient-seated gate valve with bolted cover connection and socket connection on both sides for boltless connection to the VAG BAIO®plus System.

- O-rings: EPDM

- Body: Welded steel S235JR (St.37-2)

- Valve sealing: EPDM

- Disk: Welded steel S235JR (St.37-2)

- Butterfly valve stem: Stainless steel 1.4021

- Shaft bearing: Zincfree bronze

- Seat: Stainless steel, microfinished

Electrofusion is a quick and easy method to connect polyethylene (PE) pipes. Prefabricated fittings are used, incorporating an electrical heating coil which melts the plastic of both the fittings and the pipe, causing them to fuse together. Below are the proper process for an electrofusion fitting jointing.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.