Easier and reliable way for pipe jointing

FUIS Poly Push-Fits System

Poly push fit fittings offer a revolutionary approach to HDPE (High-Density Polyethylene) pipe jointing, utilizing compression and push-fit principles or mechanical methods instead of heating techniques. This compression jointing method presents a seamless, cost-effective, and fast solution for connecting HDPE pipes in various applications.

HDPE pipes, renowned for their durability, flexibility, and resistance to corrosion, are widely used across industries for conveying fluids and gases. Traditionally, joining HDPE pipes involved heating the material to a molten state and then fusing the ends together. However, with the advent of poly push fit fittings, this process is replaced by a simpler and more efficient method.

Poly compression push-fit fittings are crafted from polypropylene, a material known for its robustness and chemical resistance, ensuring longevity and reliability in diverse environments. These fittings boast nominal pressure ratings of PN10 and PN16, making them suitable for cold water applications where durability and leak-proof connections are paramount.

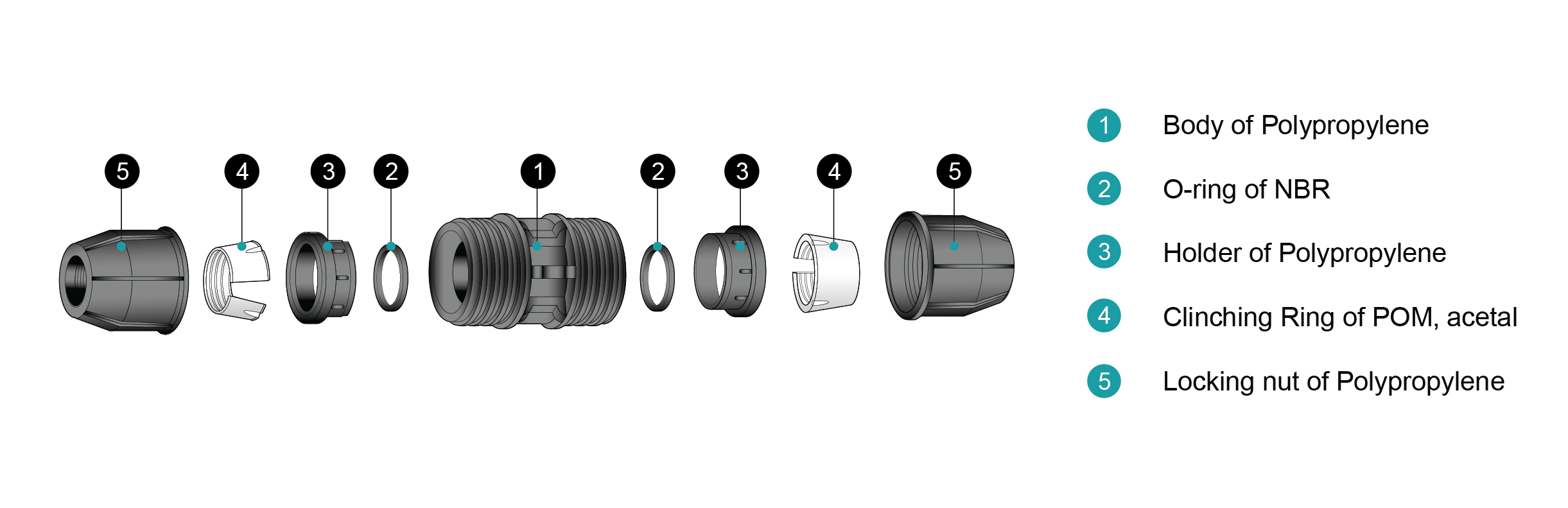

Poly-Fit fittings ingenious design features aimed at facilitating effortless installation and ensuring secure jointing. Equipped with O-rings and screw nuts, the fittings provide a tight seal, effectively preventing leakage and ensuring system integrity. The incorporation of O-rings enhances the fittings’ ability to withstand varying pressures and temperature fluctuations, making them ideal for demanding industrial and commercial settings.

One of the key advantages of poly push fit fittings is their ease of installation, which significantly reduces labor costs and minimizes downtime. Unlike traditional methods that require specialized equipment and skilled labor, the compression jointing process can be carried out quickly and efficiently by personnel with minimal training. This streamlined installation process translates into substantial savings in both time and resources, making poly push fit fittings a preferred choice for projects with tight deadlines and budget constraints.

The versatility of poly push fit fittings allows for seamless integration into existing piping systems or new installations. Whether used in plumbing, irrigation, industrial processing, or municipal infrastructure projects, these fittings offer unparalleled adaptability, enabling engineers and contractors to customize solutions tailored to specific requirements.

Another notable benefit of poly push fit fittings is their durability and resistance to corrosion, making them suitable for a wide range of applications, including aggressive chemical environments and outdoor installations. Unlike metallic fittings, which are susceptible to rust and degradation over time, polypropylene fittings exhibit excellent resistance to chemical attack, ensuring long-term performance and reliability.

Poly push fit fittings also offer environmental benefits, thanks to their recyclability and eco-friendly manufacturing processes. By opting for these fittings, organizations can reduce their carbon footprint and contribute to sustainability initiatives without compromising on performance or reliability.

Advantages of HDPE Poly Compression Push-Fit Fitting

Poly push fit fittings provide exceptional versatility, seamlessly integrating into both existing piping systems and new installations. Whether applied in plumbing, irrigation, industrial processing, or municipal infrastructure projects, these fittings offer unmatched adaptability. Engineers and contractors can easily customize solutions to meet precise requirements, thanks to the flexibility these fittings afford.

Poly Compression Fitting system offers several advantages over other jointing techniques. Some of the key advantages are :

Strong and leak-free joints

HDPE butt-fusion creates a strong, seamless, and leak-free joint between the two components. The fusion process involves melting the two ends of the components and then fusing them together under controlled pressure. This results in a joint that is resistant to leaks and other types of damage.

Cost-effective

The HDPE butt-fusion system is a cost-effective jointing technique. The process is relatively quick and requires only a small amount of energy to complete, making it a cost-effective solution for joining HDPE components.

High efficiency

The HDPE butt-fusion system is a highly efficient jointing technique. The process is relatively quick and requires minimal preparation and set-up time.

Reduced maintenance

HDPE butt-fusion creates a joint that requires minimal maintenance over its lifespan. The joint is resistant to corrosion and other types of damage, reducing the need for costly repairs or replacements.

Durability

HDPE butt-fusion creates a joint that is highly durable and resistant to damage from chemicals, abrasion, and environmental factors.

Environmentally friendly

The HDPE butt-fusion system is an environmentally friendly jointing technique. HDPE is a recyclable material that can be reused and repurposed, reducing waste and environmental impact.